TopSolid PDM Web Explorer | จัดการไฟล์ CAD/CAM อย่างมืออาชีพ

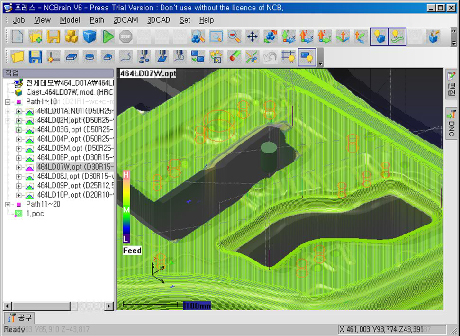

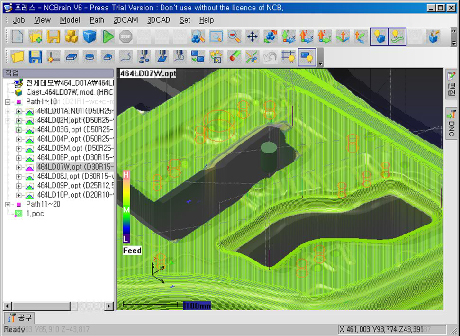

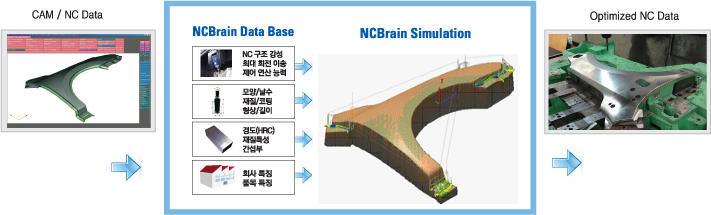

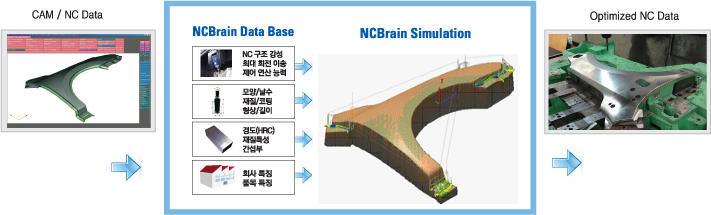

NCBrain Mold & Press

NCBrain Optimization Demo Video

NCBrain Introduction video

Top-notch standard solution for NC milling by optimized database

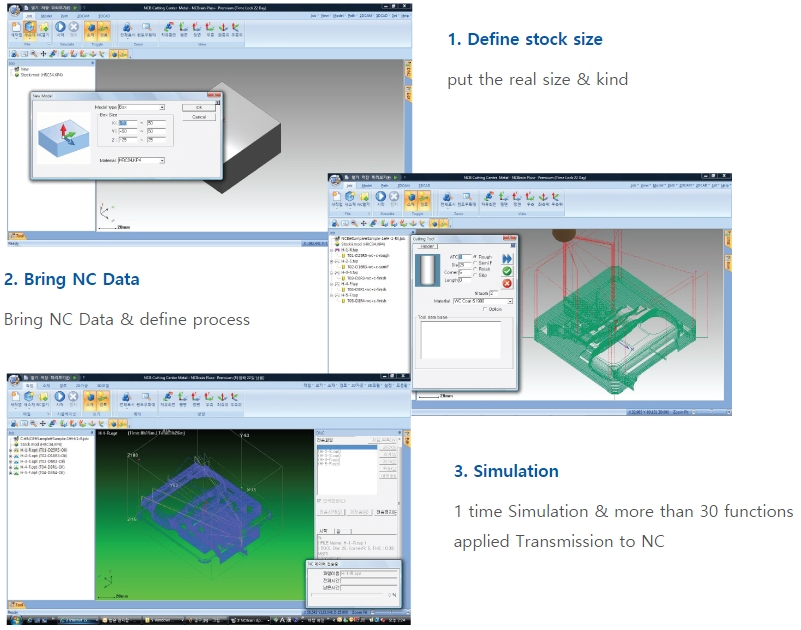

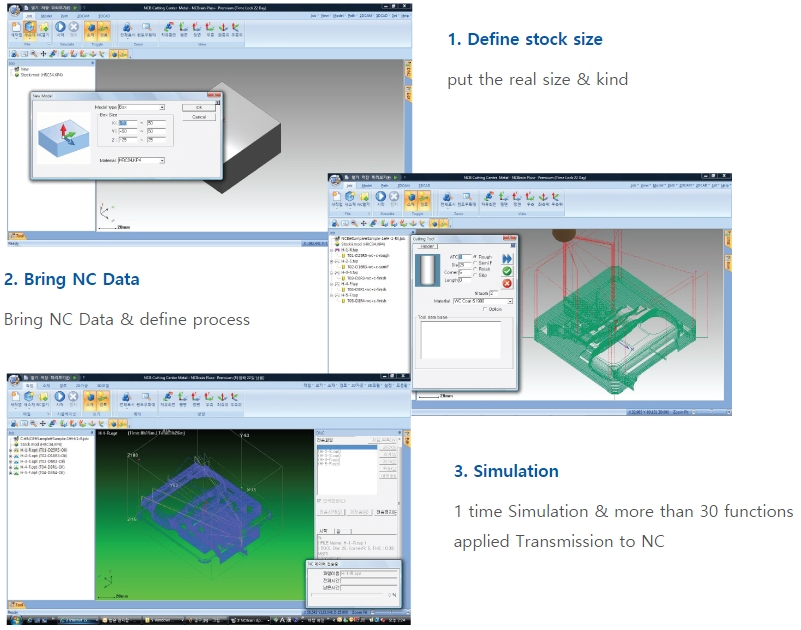

How to use NCBrain

NCBrain main functions

Main functions by best Data Base automatically

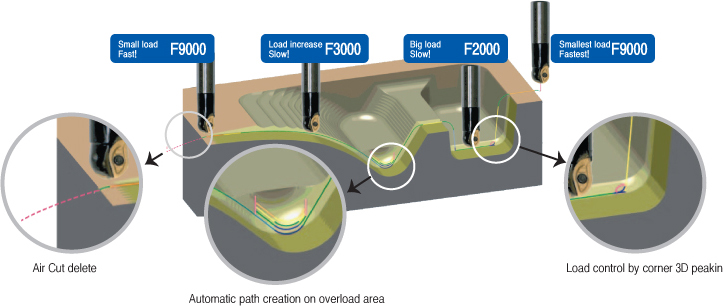

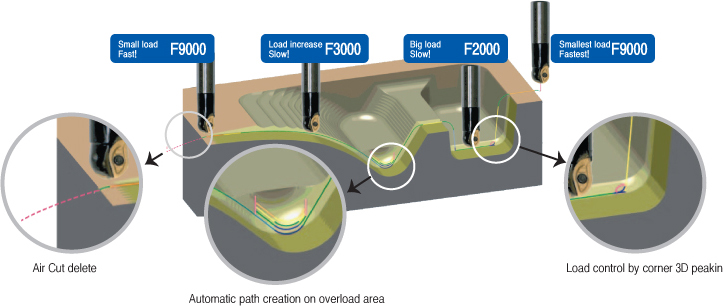

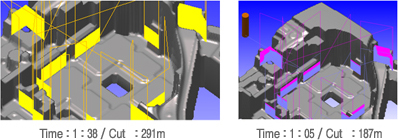

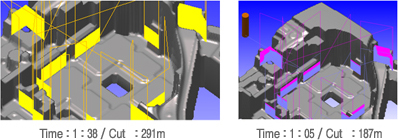

Feedrate control, toolpath creation, air cut delete

After 1 simple Simulation, more than 30 functions are realized such as feed rate control, time reduction, automatic tool path addition on overload area, prevention of tool breakage etc. This makes it possible to do fast and safe NC milling even at night without stopping by ATC.

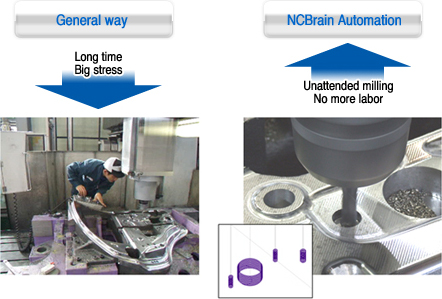

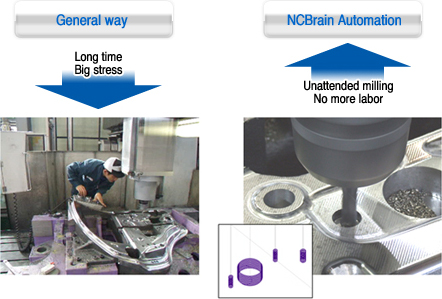

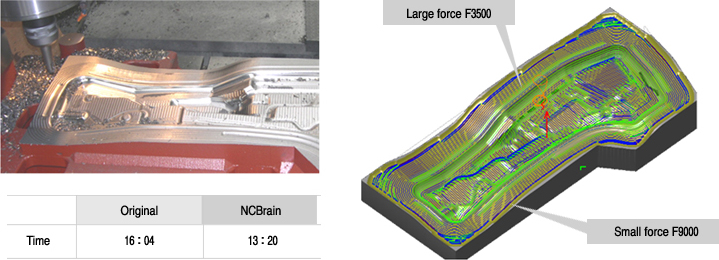

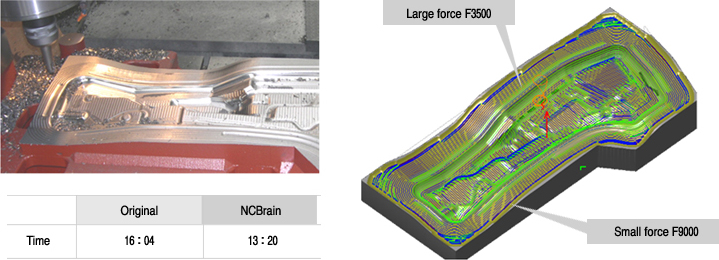

Effectiveness of NCBrain & Faculty of NCBrain

Effectiveness of NCBrain

– Reduction of milling time by optimized terms & upward Run@rate by continuous ATC use

– Prevention of tool breakage & easy process control by optimized milling information

– Quick ROI & easy, immediate manipulation

– Prevention of tool breakage & easy process control by optimized milling information

– Quick ROI & easy, immediate manipulation

Faculty of NCBrain

– Best ideal database for NC milling by various tools specification

– Automatic Feedrate & RPM control by automatic load calculation

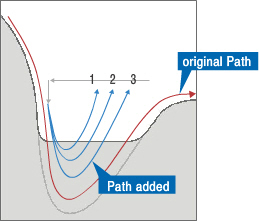

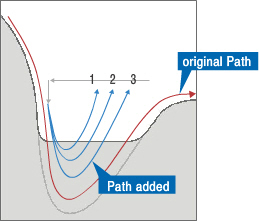

– Automatic toolpath addition for excessive load to cut

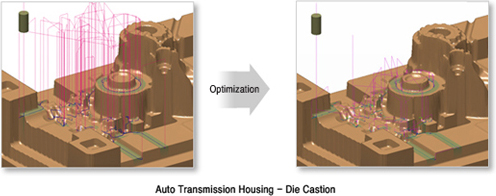

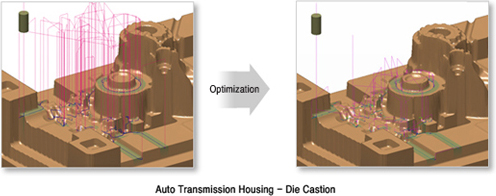

– Automatic aircut delete for empty & little load to cut

– More than 30 functions autualized after 1 simple simulation

– Automatic Feedrate & RPM control by automatic load calculation

– Automatic toolpath addition for excessive load to cut

– Automatic aircut delete for empty & little load to cut

– More than 30 functions autualized after 1 simple simulation

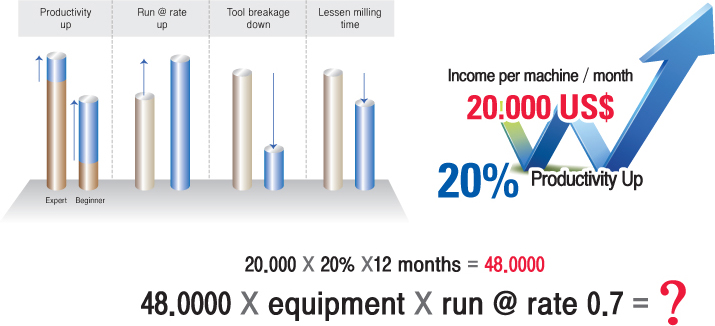

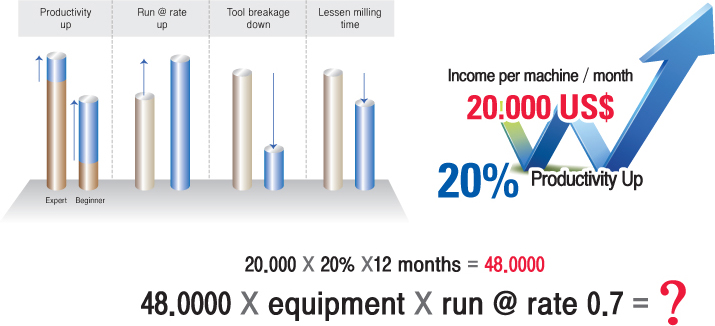

ROI

Profit rate by CNC numbers per year

Customers & Application

Appox.1700 clients 7000 COPY From Top Global company to small company, using our S/W

The best optimized system used in electronics, car, mobile variety product of press, mold, die-casting and blow-mold by NC machining part with data base.

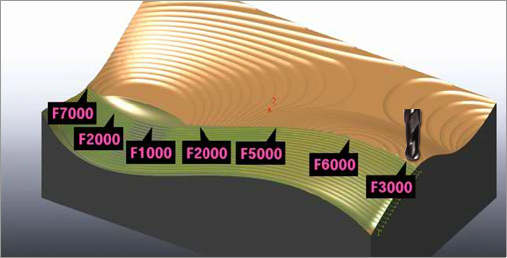

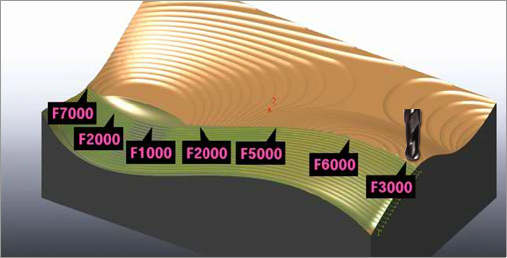

Feed rate controlSave milling time and prevent tool breakage Calculating Cut Load, Add Optimized Feed Rate Automatically Cutting load is continuously changing along the work shape. For this part, normal feed rate would be F1000. But now, NCBrain controls feed rates, from F800 to F4000 automatically. Faster and safer machining is possible. |

|

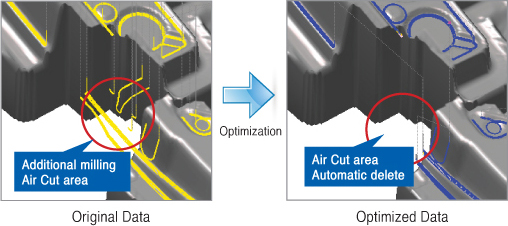

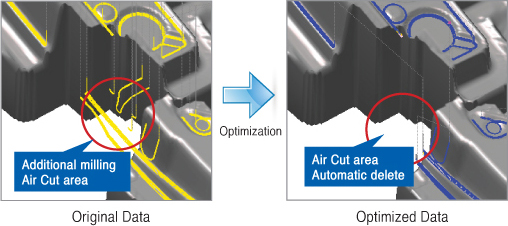

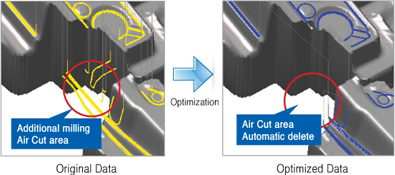

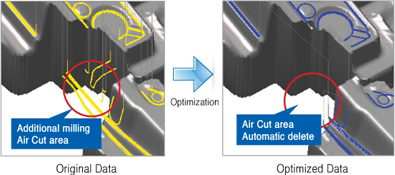

Air Cut deleteSave time, easy CAM job Unnecessary tool path called ‘Air Cut’ reaches normally to 5% to 30%. This Air Cut paths should be deleted. NCBrain deletes unnecessary Air Cut paths automatically, and make easy CAM job accordingly. |

|

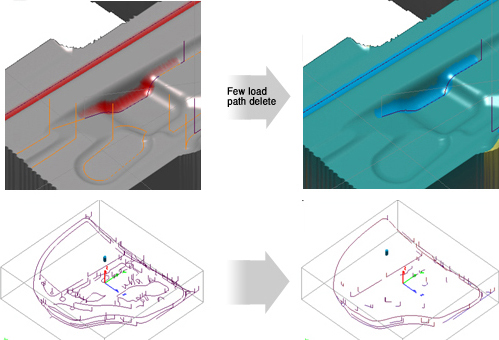

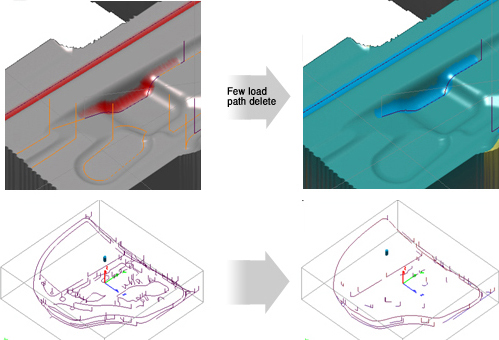

Few load path deleteReduce time in roughing & semi This function makes rapid machining on thin load area automatically. The small remained load will be cut later by necessary process. |

|

G0 height control

reduce time & prevent collision Along the shape and height of stock, G0 rapid motion shall be controlled for higher efficiency. Also NCBrain creates approach paths as G01 code.  |

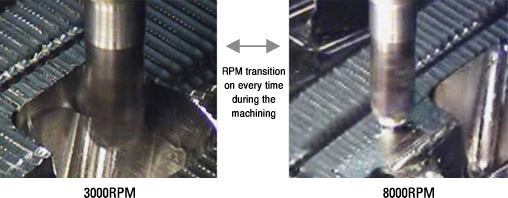

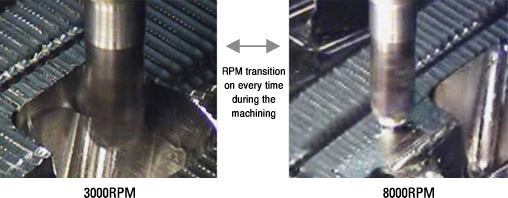

RPM controlalong the contact point of tools. Spindle should be changed by different condition such as along the work shape and location. NCBrain makes it possible accordingly. |   |

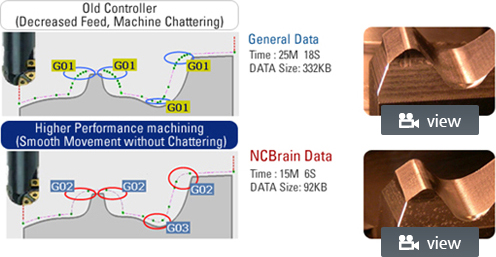

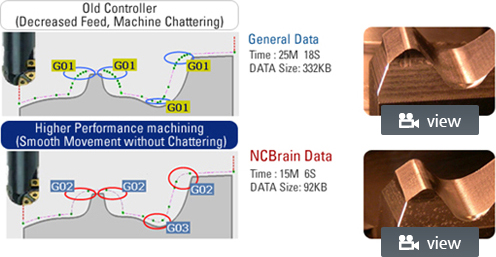

Arc functionGood for old machine in saving time and high quality Line(G1) to Arc(G2, G3) Translation and Look ahead Feed Control for Adjusting NC data to old Controller Machine As a function of old-type instrument, it solves problems by circling of corner part, which has large data and accelerating/decelerating automatically. (General movie) as you know, there are many problems of over cutting quality lowering by dropping feed and shaking at the corner. But, (ARC movie) the following shows smooth ac/decelerating and clear manufacturing. The processing time reduced 30% and the quality increased |

|

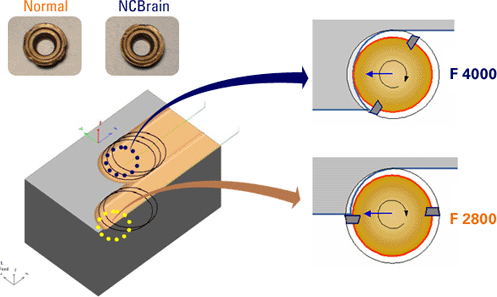

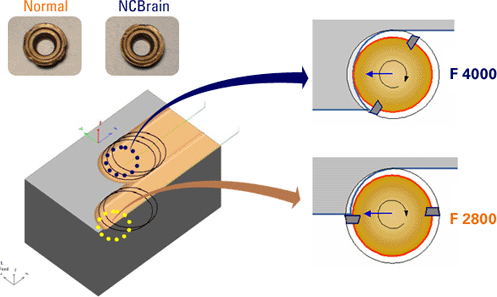

Bull-nose feed rate controlTool life longer, time reduction According to entry and location, feed rate of bull-nose should be controlled like an example above. This can reduce time and make tool life longer. |

|

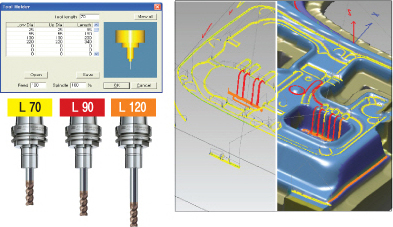

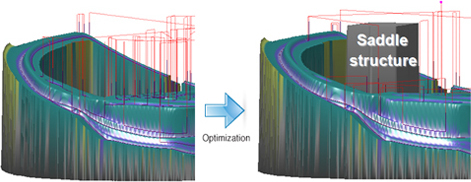

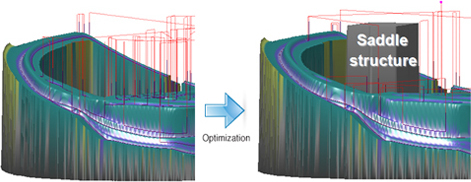

Tool path addition on overload

Prevent tool breakgae & low quality Overload area can cause tool breakage, low quality, and over cutting. NCBrain can handle these problems with self-creating tool path on extremely loaded area.

|

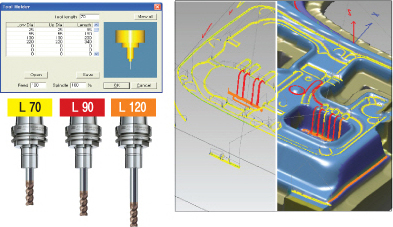

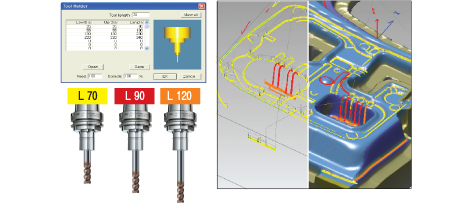

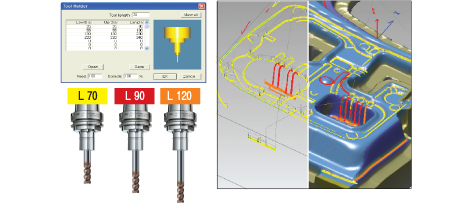

Best tool length information

Optimized tool chucking According to the tool length, minor and major accidents can happen all the time. NCBrain shows optimal length information after 1 simulation. So, fast and safe milling can be done simply.

|

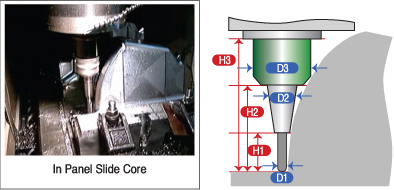

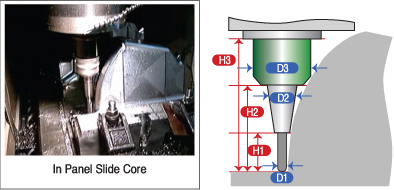

Tool length divisionshort and long length area for safe milling Because of small deep area, the whole inefficient milling can happen more often than not. NCBrain divides these NC data by diameter and length of the cutting tool, which makes efficient milling accordingly. |

|

Prevent collisionCreate ramp entry NCBrain checks and prevents accidents of the cutter. NCBrain changes the straight approach into ramp approach automatically. |

|

3D peakingSmooth machining at the corner The sensitive section is the corner. NCBrain creates 3D peaking paths, not a direct way. It offers much more stable and smooth machining. |

|

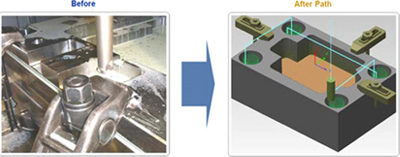

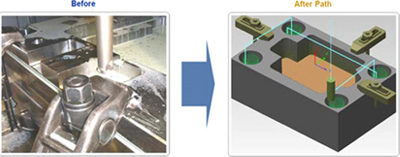

Prevent clamp collisionAvoid collision with clamp Defining the clamp location, G0 tool paths will be adjusted for avoiding crash with clamps. |

|

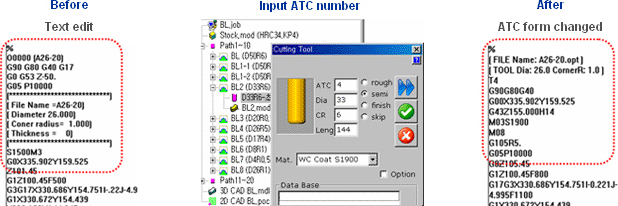

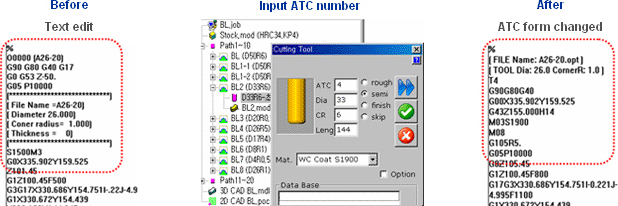

ATC formT number change only, automatic coordinate insert and one NC data Just input the number of ATC, NCBrain changes the NC data head section with ATC code form. And work coordinate codes are also simply added. |

|

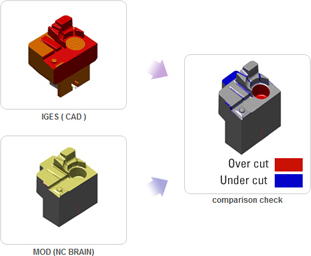

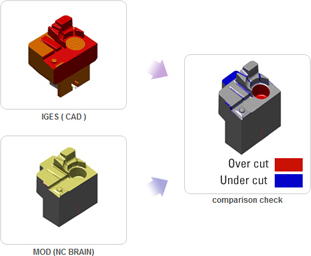

Verification of under & over cuttingCheck in advance NCBrain detects differences between the CAD model and the simulated model output comparison result by color. The blue shows electrode discharge machining |

|

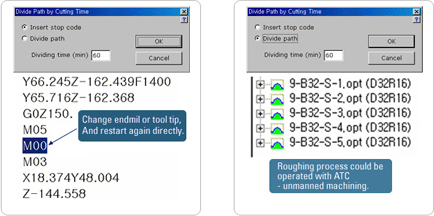

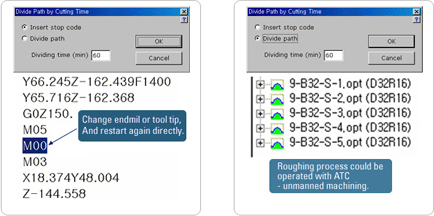

Tool life controlDivide NC data based on tool lives for safe milling Input the life time of various tools, and NCBrain divides NC data. M00 code will be inserted at the G0 rapid motion. Or, dividing path option will separate one file into several files with ATC form. |

|

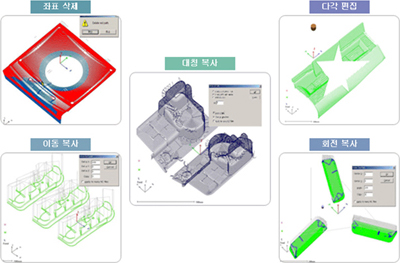

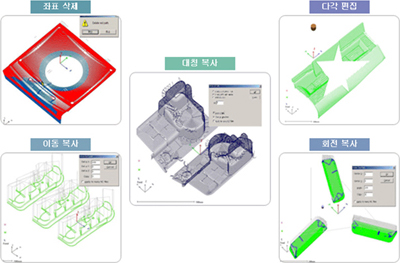

Graphic editEasy edit for NC Data NCBrain has the tool path edit functions such as cut off, move, rotate, and symmetrical edit. This simple edit function gives conveniences to the NC operator. Metallic pattern or electrode has lots of the symmetry core. NCBrain makes all data to symmetry downward cutting automatically for the immediate process. |

|

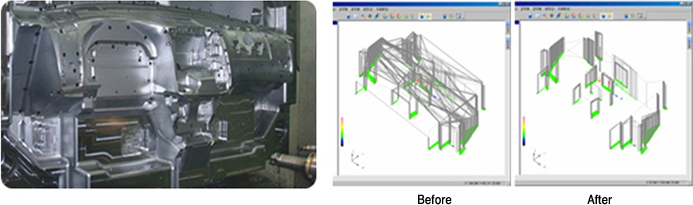

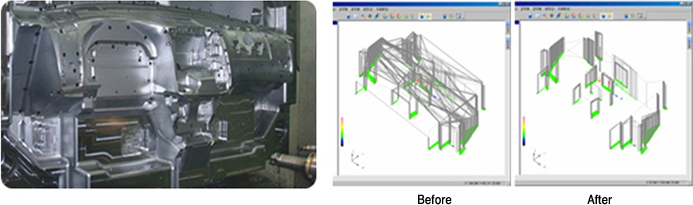

Order of processConsidering G0 numbers and distance NCBrain could re-arrange cutting order to reduce time when G0 paths are too many. |

|

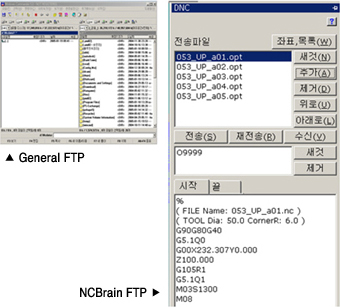

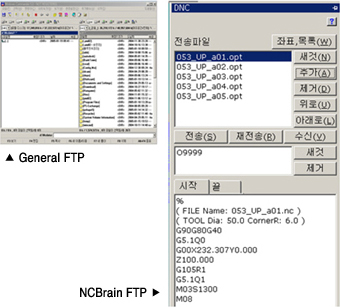

FTP transmissionconvenient network transmission Using the data server has to follow several steps normally. NCBrain has FTP function that helps to skip these complicated tasks. One click will do. |

|

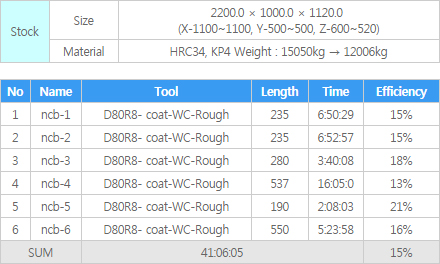

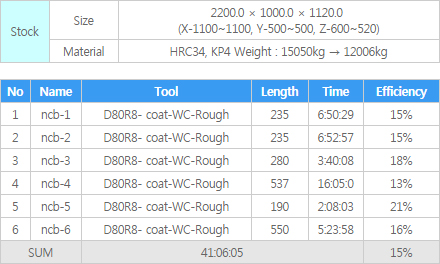

Work sheet output – easy jobAfter simulation, NCBrain outputs worksheet showing work size, weight, tool length, and time etc. Cutting time is very correct because NCBrain calculates the machine's acceleration (as G1 motion, G0 rapid motion) and also the feed rate changes. |

|

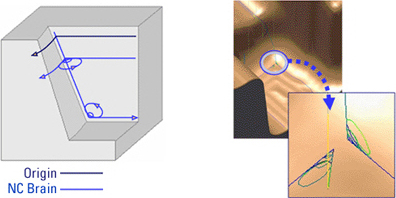

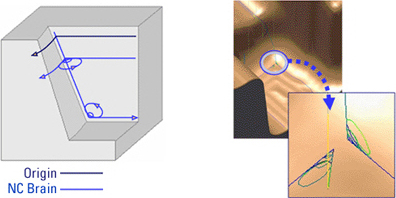

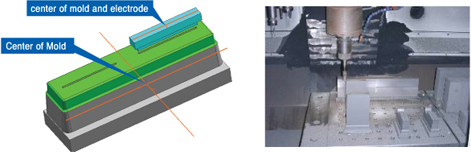

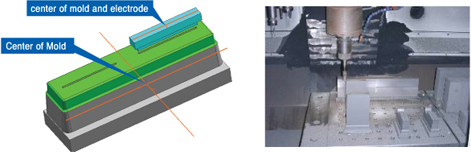

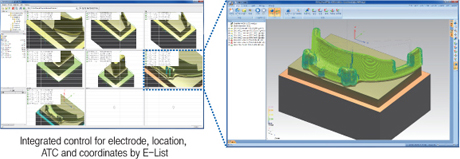

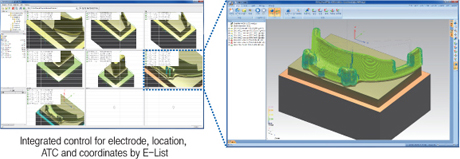

Analysis of Graphite machiningThe center of mold and electrode is usually different, which causes the set up of multi coordinates and difficulties of ATC control. |

|

| E-List makes graphite centering and can control multi graphite machining process and ATC. |

|

| You can control milling process and ATC tools. Also, you can bind and send various NC data at a time. |

|

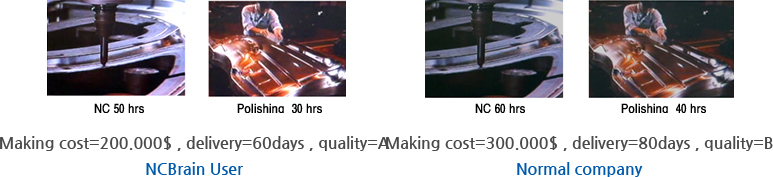

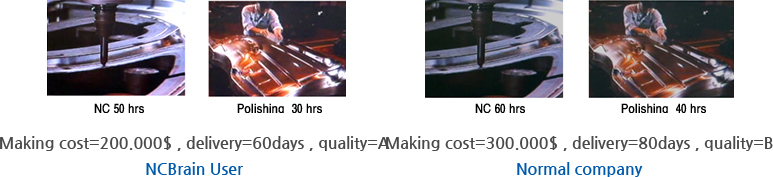

NC machining - cost !

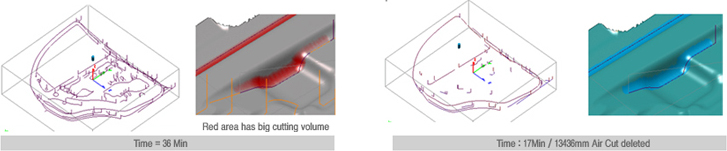

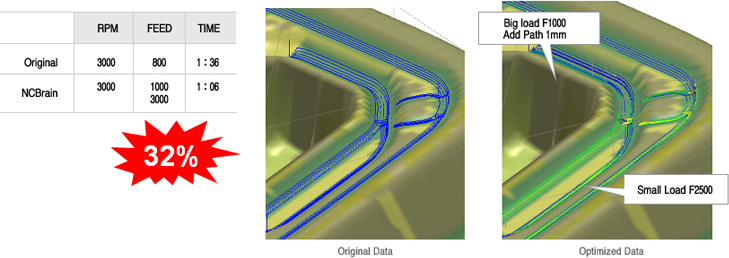

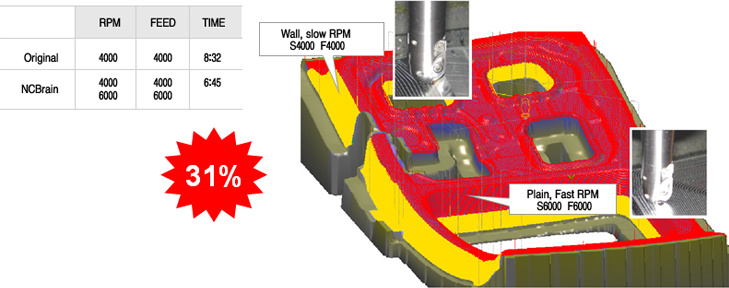

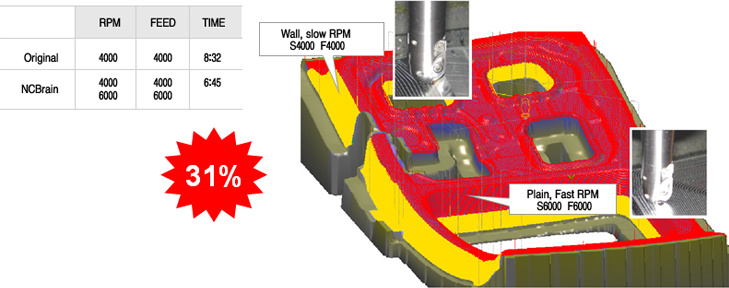

Case of feed control

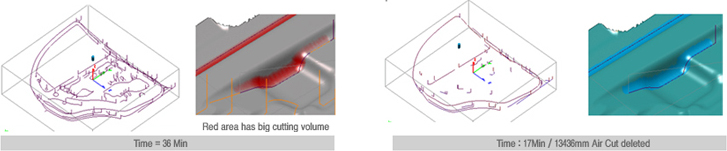

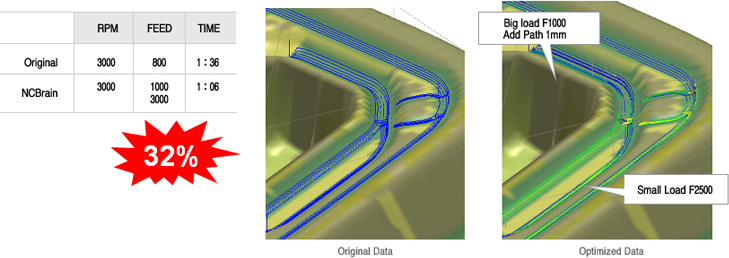

AIR CUT delete - faster milling

Air Cut deleted automatically - easier CAM work

Structure Milling- Air Cut delete

Air Cut delete for Dia-Compensatied 2D data for Structure milling

Remove very slight cutting paths

Remove paths where the cutting volume is very small in Roughing or Penciling process

Case of path addition & Feed control

Semi-finishing, Ball30, Stock allowance 0.3 → Ball16 Stock allowance 0.3 pitch=2mm

Case of RPM control

RPM control milling by refering to engage point- Ball Center or Ball Outer

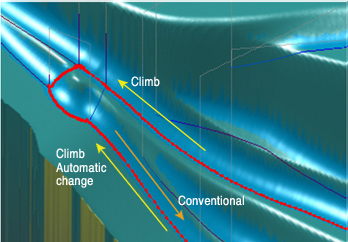

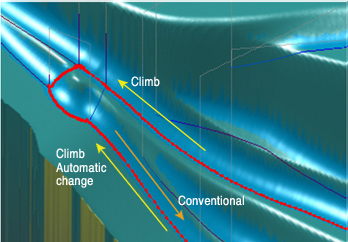

Automatic change the direction to climb cutting

Check out conventional cutting paths in Pencil process, Change to climb cutting direction

Shortest rapid move - recognize the work shape

Time cut by adjusting rapid move height

Divide NC data according to tool length itself!

Use the tool length information, devide paths along the work shape

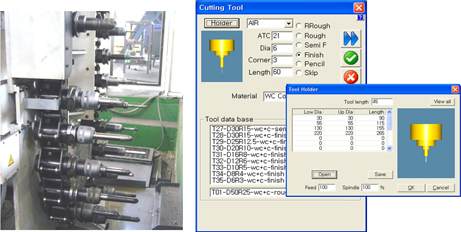

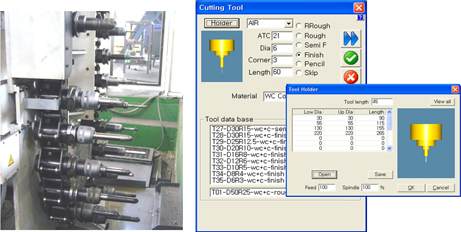

Self tool management from ATC magazine

Self ATC magazine management- tool shape, length, holder Automatically divide NC data along the tool & holder shape

Button Die milling automation